- Flexible

- Scalable

- Repeatable

- Traceable

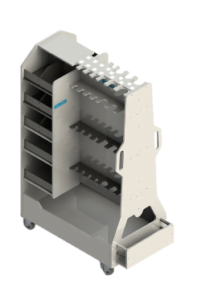

DPF Plastic Design Solutions

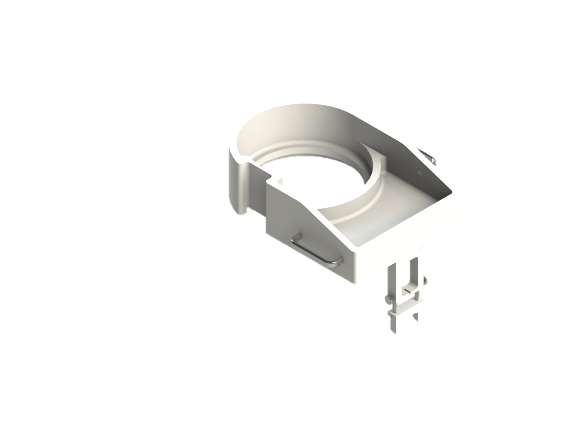

DPF have extensive experience in providing bespoke engineered solutions in a variety of materials, including plastics. Operating within highly regulated industries such as Med-Tech, Aerospace and High Tech, plastic is often the best material solution to be used.

Plastics used by DPF include HDPE, Polycarbonate & Polypropylene etc. all are FDA compliant & approved, assisting in various applications, particularly within Cleanroom environments.

Challenging

Engineering

Thinking

24/7

Approved High Performance Materials

The chemical resistance properties of the plastics used protect against corrosive chemicals (nitric acid, hydrochloric & hydrofluoric acid), in addition to the nonporous characteristics make plastic an ideal material for varying applications, including cleanroom environments.

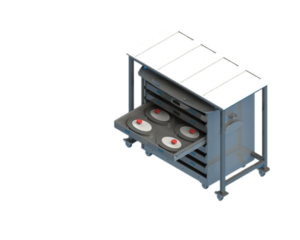

In conjunction with DPF modular designed solutions, which can include items such as anti-static casters, plastics can limit contamination and conditions like dust & static electricity. By dissipating static electricity and with low outgassing characteristics in a vacuum-sealed environment, certain plastics are an ideal option for Semiconductor, Pharma & Bio-Tech cleanrooms.

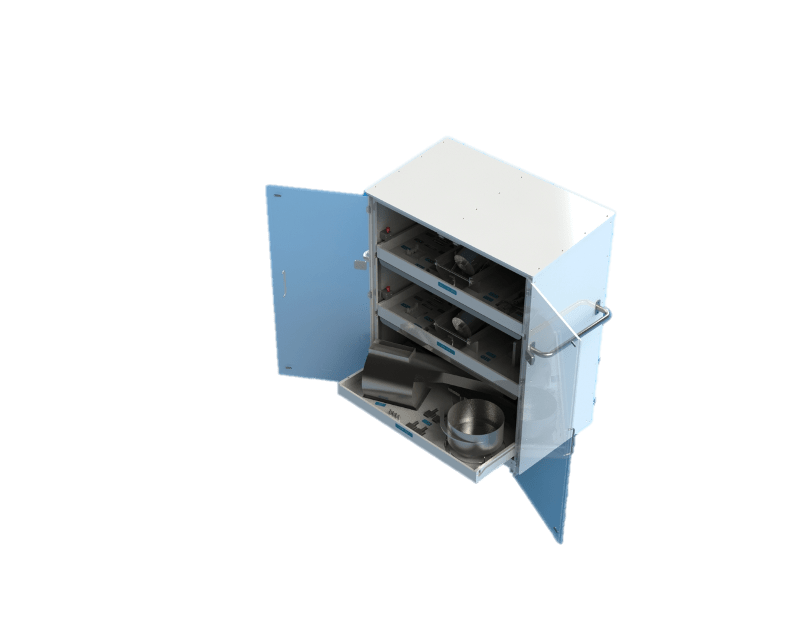

6 S Compliance

Solutions incorporating shadow boards, etc.

Health & Safety

TPA locking mechanisms available, reduced weight with easier mobility

Cost Reduction

Higher Impact resistance, replacement costs, modular designs, tool protection etc.