The last few years have seen significant change in the industry. Companies have adjusted their forecasts and many of the existing processes that have defined their long-term targets are being re-evaluated. In periods of great change and uncertainty, opportunities for new industries and technologies can arise.

Globally, there is an emerging trend in using more sustainable technologies that help eliminate waste. Users are becoming more aware of their carbon footprint and increasingly seek better, cheaper, greener technologies. Competition to source high quality material and a reliance on creating local networks for manufacture and distribution is becoming more central to quicker lead times as customer demand increases.

The industry outlook remains positive. For example, it has been estimated that the global 5-Axis CNC machining centre market size will experience compound growth of 5.67% annually and reach $3.6 billion by 2028. This considers emerging market trends, the impact of COVID-19, supply chain issues and potential regional conflicts.

Higher degrees of specialisation, better software management tools to undertake complex tasks, greater automation to take away many of the more cumbersome processes, thereby removing human error – Ireland is no different to the technological demands that currently exist in the market.

Industries like med-tech, aerospace and semiconductor have seen steady growth. Aerospace, an industry severely impacted by Covid, has recovered in most countries. Companies in this sector will seek to recover some of the losses felt in 2020 and 2021. Budgets for investment, which would otherwise have been spent in R&D and developing more advanced technologies or tooling solutions, may be more conservatively deployed.

The Landscape in Ireland

The precision engineering sector in Ireland is highly competitive and continues to attract new business from around the world. Considered Europe’s med-tech hub, the Irish government offers a number of tax incentives for companies in Ireland including Research and Development (R&D) tax credits, grants for capital investment, innovation vouchers, regional development funds and other tax reliefs.

Ireland continues to be an excellent location for businesses in this sector. A rich and diverse pool of workers, strong labour market, favourable working conditions and competitive landscape lead to a higher degree of competition which improves the standard of products made available. Organisations like Enterprise Ireland help support SMEs, offering funding and advice. The Enterprise Europe Network consists of over 600 organisations that similarly provide guidance.

The clients that we work with at DPF are international in scope and we ship goods globally – around 60% of our sales come from exports. It is the strength of our network that sets us apart from many of our competitors. Investing in new equipment and software, and leveraging existing relationships to form a win-win solution that benefits both parties ensures that we have the necessary skills and knowhow to wade through uncertain waters.

A Look Ahead

The increasing prevalence of technology in our day-to-day lives looks likely to continue. Robotics are already used in the field of medicine, performing complex surgeries – often by a team working remotely. In the automotive industry, six-axis robots are deployed in material handling jobs such as welding, mounting door panels, etc. The emergence of OpenAI in late 2022 looks likely to disrupt the world of written media.

As we become more comfortable with new technologies and machines working in tandem with their human operators, each of us must learn how to integrate these tools into our working environment so that they serve us and improve or automate many of the tasks which we find tedious, cumbersome or too complex.

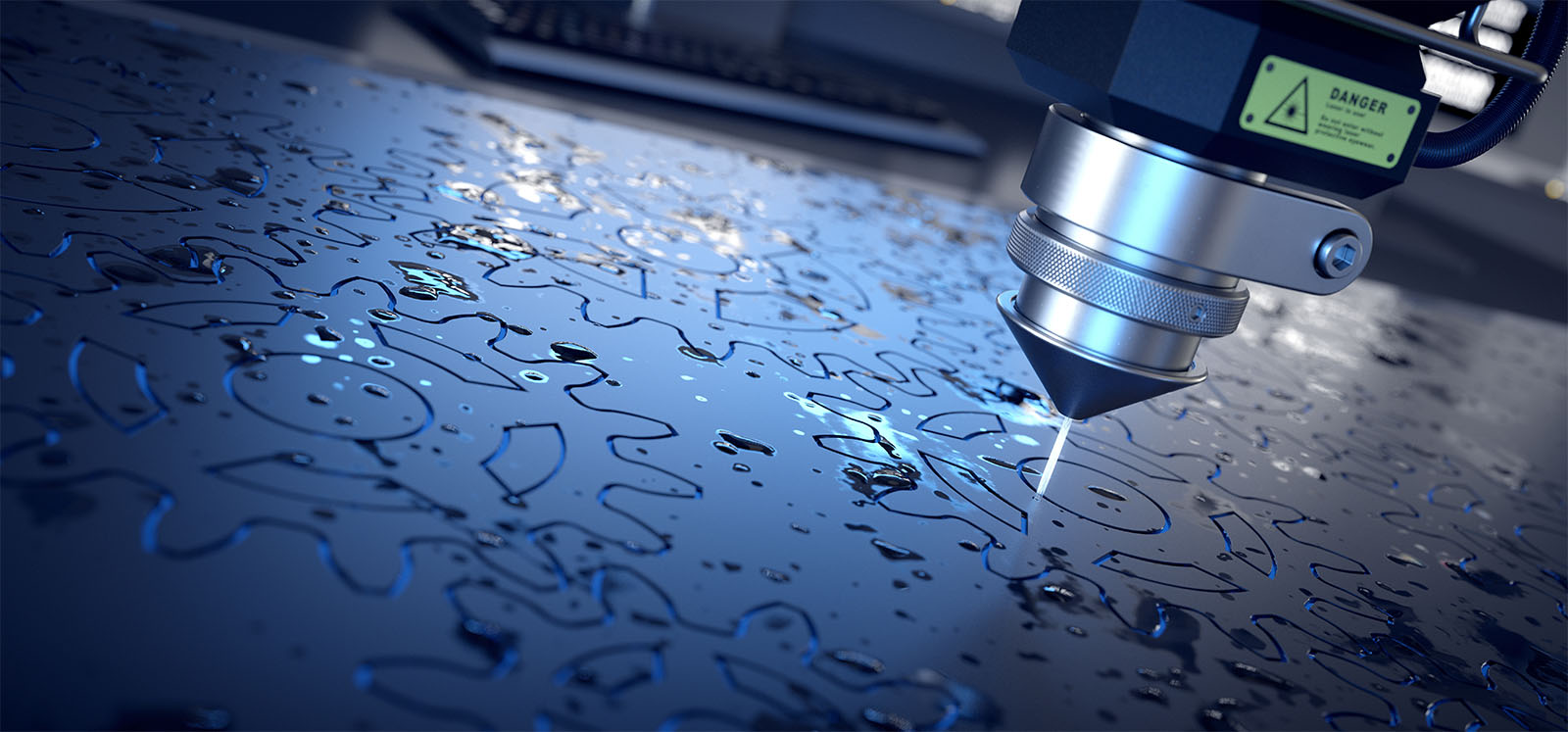

Some tasks are only achievable by machines. At DPF, when manufacturing clean precision parts with micron accuracy, technology needs to be leveraged. In precision engineering, manufacturing machines have the ability to eliminate the risk of human error, ensure ISO compliance and ultimately provide a solution that meets the needs of the client. The degree of specificity and attention to detail of many precision engineering tools can only be accomplished by machines. In the future, this high degree of specialisation, shorter project life cycle and the need for automation will only increase.

At DPF, our in-house design team oversees each project, and over 90% of our precision tooling business is ‘design-to-build’. Operating in tightly regulated industries requires the best technologies working in concert with highly skilled operatives to create, in many cases, bespoke fixtures and tooling design, such as metrology fixturing or MRO in the manufacturing process.

Specialisation will require unique insights and tools, often only achievable with the right skillset and technology stack.

Don’t Forget Who Runs the Machines!

Although technology will continue to evolve, it is vitally important to continue to invest in the staff of the company. Crucially, existing and future members of the team need to be comfortable with adopting newer technologies. The industry continually evolves and purpose-built machines can be leveraged in new and exciting ways. In many cases, it’s the small margins that can make a significant difference. Whether it be cutting down on lead times, intricacies in precision tooling or design manufacturing nuances; new technologies and the capacity to get the most out of them should be embraced to extract the maximum return on investment. At DPF, we offer a wide range of supports so that as a collective we are always improving.

Clients will be more conscious of their spend in the near-term and expect the same high quality products at or below previous prices. Machines and new technology can figuratively do much of the heavy lifting, but they will never replace the human connection – namely, the relationship between two teams or companies working in tandem to deliver a high quality product. Failure to upskill and integrate newer technologies in what is already a highly competitive industry, will have consequences as the industry continues to grow, and ever more specialised solutions are sought.

Here at DPF, we are supply chain experts that provide a world-class service at very competitive prices. Over a decade of experience in the industry means that we have been at the forefront of cutting edge technologies, and working with dozens of clients on often complex builds means that there is very little that we haven’t encountered.

If you have a specific project in mind and would like to speak with one of our team of experts, you can contact us here.